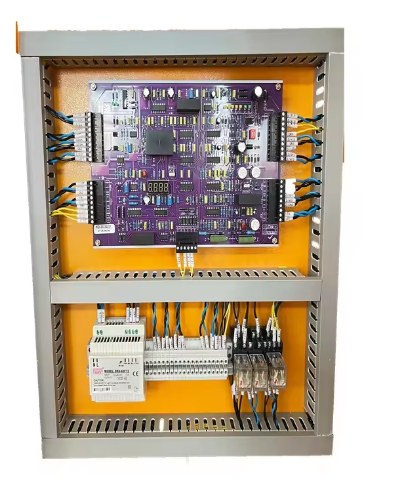

In medium-frequency induction heating equipment, the low-harmonic IGBT power cabinet is the core electrical control unit. By leveraging advanced IGBT technology and harmonic mitigation technology, IGBT power cabinets are gradually replacing traditional thyristor power cabinets and becoming the mainstream choice in the field of medium and high-frequency induction heating. This IGBT power supply is specially designed for precision, energy efficiency and unparalleled reliability, ensuring seamless integration with induction heating systems in industrial applications, reducing costs and enhancing production efficiency.

I. Core Advantages of Low-Harmonic IGBT Power Cabinet

Highly efficient and energy-saving

IGBT supply unit has a high switching frequency (typically between 1 and 20kHz), and its switching loss is much lower than that of thyristors. The power conversion efficiency of IGBT supply unit can reach over 95%, saving 10% to 20% energy compared to thyristor power cabinets.

Precise temperature control and strong heating stability

IGBT power supply supports closed-loop digital control, allowing real-time adjustment of output power, frequency and current. The temperature control accuracy can reach ±1℃, meeting the requirements of precision heating processes. Compared with the open-loop control of thyristors, IGBT power supply can avoid overheating or underheating, improve the consistency of product processing, and are especially suitable for overseas customers with high requirements for process accuracy.

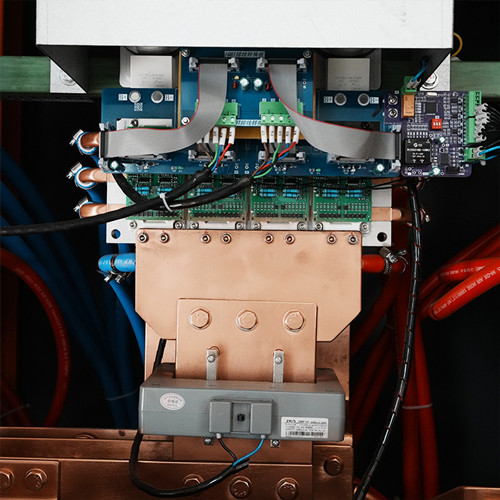

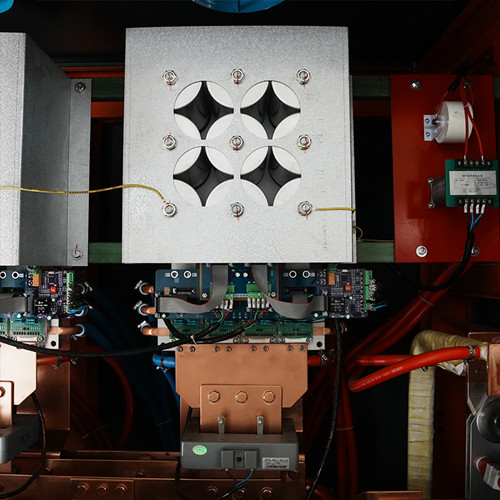

IGBT power cabinet is small in size, light in weight, and easy to install and maintain

IGBT supply unit have a high degree of integration and do not require large reactors or filter devices. The volume and weight of IGBT power cabinet are only 1/3 to 1/2 of those of a thyristor power cabinet of the same power. This not only saves factory space, but also reduces equipment transportation costs. Meanwhile, the modular design makes troubleshooting and component replacement simpler, reducing the difficulty of after-sales maintenance for overseas customers.

IGBT supply unit has a strong overload capacity and is suitable for complex working conditions

IGBT supply unit features excellent overcurrent and overvoltage protection characteristics, capable of withstanding short-term overload currents ranging from 150% to 200%, and can adapt to complex working conditions with significant variations in load impedance during induction heating.

Low noise and minimal electromagnetic interference

The switching frequency of IGBT power supply is far away from the power frequency noise band, and the noise during operation is lower than 60dB, improving the working environment in the workshop. At the same time, by optimizing the circuit design, electromagnetic interference (EMI) has been significantly reduced.

Low harmonics

The IGBT power supply adopts soft-switching technology, avoiding the sudden changes in voltage and current, which significantly reduces the harmonics generated during the switching process, especially the high-order harmonics.

2. Typical Application Scenarios of IGBT Power Cabinets

Medium-frequency induction melting furnace

IGBT supply unit is suitable for the smelting of cast iron, cast steel, copper, aluminum and their alloys, and is a core equipment in the foundry and metallurgical industries. The IGBT supply unit can quickly start smelting, precisely control the furnace temperature, shorten the smelting cycle, and at the same time, IGBT power supply has a significant energy-saving effect. IGBT supply unit is suitable for small and medium-sized foundries and overseas metal smelting enterprises.

Medium-frequency induction heating furnace

IGBT supply unit is used for preheating metal workpieces before forging and heating billets before hot rolling. The precise temperature control feature of IGBT power supply can ensure uniform heating of workpieces, reduce forging cracks, and improve the quality of forgings. The IGBT supply unit are widely used in overseas supporting processing in fields such as automotive parts, construction machinery, and aerospace.

Medium-frequency induction hardening/annealing equipment

IGBT power supply is used for surface hardening and annealing treatment of mechanical parts such as gears, bearings and shafts. The IGBT power cabinet can flexibly adjust the heating power and time to achieve local precise quenching, enhance the surface hardness and wear resistance of parts, and meet the process requirements of high-end mechanical manufacturing. Low-harmonic IGBT power cabinet is the preferred configuration for overseas precision mechanical enterprises.

Medium-frequency induction welding equipment

The high-frequency response characteristic of the IGBT power supply enables rapid local heating welding, preventing the overall overheating of the workpiece. The welded joint has high strength and good sealing performance. The wide power regulation range and high control accuracy of the IGBT power supply can meet the customized requirements of various special heating processes.

Low-harmonic IGBT power cabinet features high efficiency, energy-saving, precise temperature control, gradually become the mainstream choice in the field of induction heating.

Contact us now to customize your IGBT supply unit!