What is Medium Frequency Induction Heating Furnace?

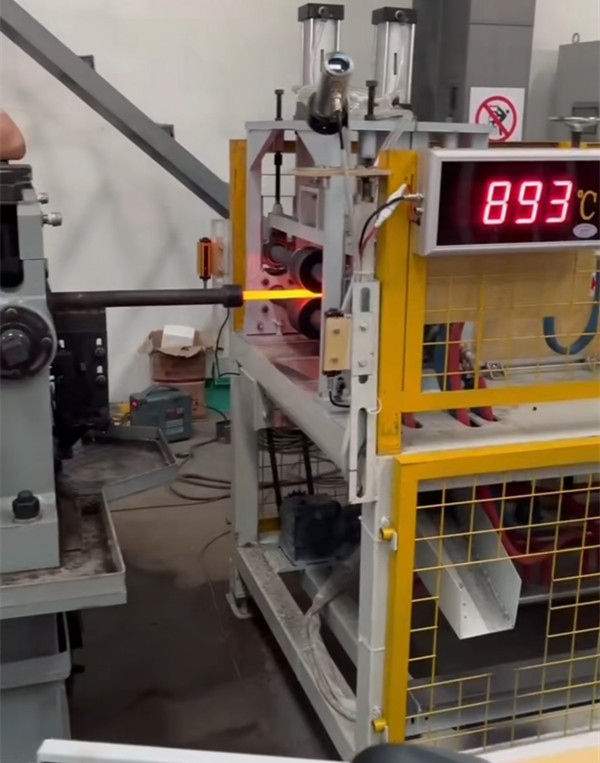

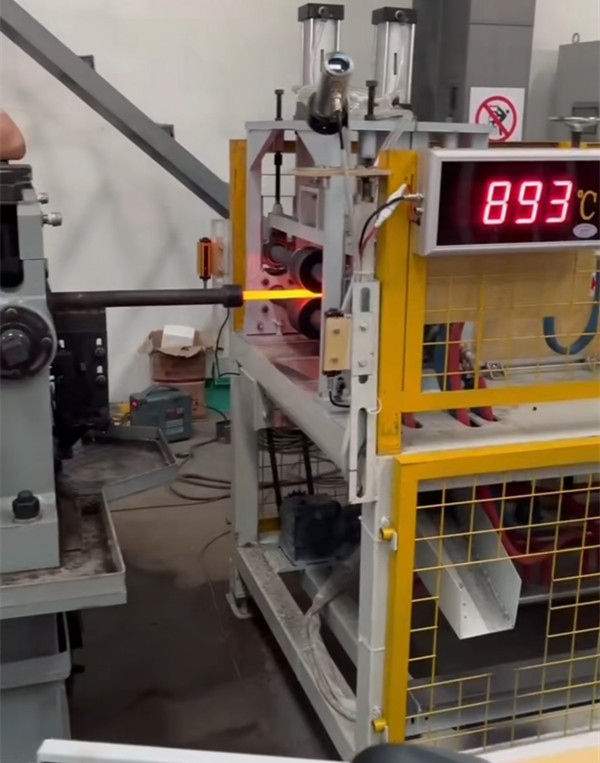

The medium frequency induction heating furnace is a advanced thermal processing device that leverages electromagnetic induction principles to generate heat within the workpiece itself, eliminating the need for direct contact between the heating source and the material. The induction heating furnace stands out for its ability to heat materials uniformly from the surface to the core, making it indispensable in high-precision industrial applications. As a crucial type of industrial induction heating furnace, it integrates advanced electrical engineering and thermal dynamics to provide efficient, controlled heating and is widely used in forging, heat treatment and other fields.

Basic Structure of the Medium Frequency Induction Heating furnace.

The robust design of industrial induction heating furnace includes four core components, each optimized for seamless performance:

lPower Supply Unit: The heart of the system, typically a high-frequency or medium-frequency inverter, converts standard electrical input into high-voltage, medium-frequency alternating current. This unit determines the heating speed and temperature range, critical for adapting to diverse industrial needs.

lInduction Coil: A custom-wound copper coil that generates a strong alternating magnetic field when energized. The shape and configuration of the coil are tailored to the workpiece’s dimensions—whether for forging, heat treatment, or other processes—ensuring maximum energy transfer.

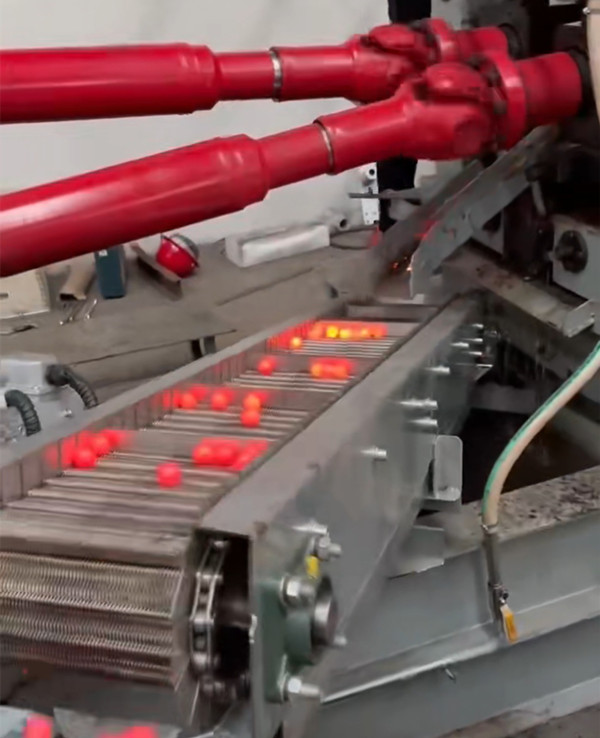

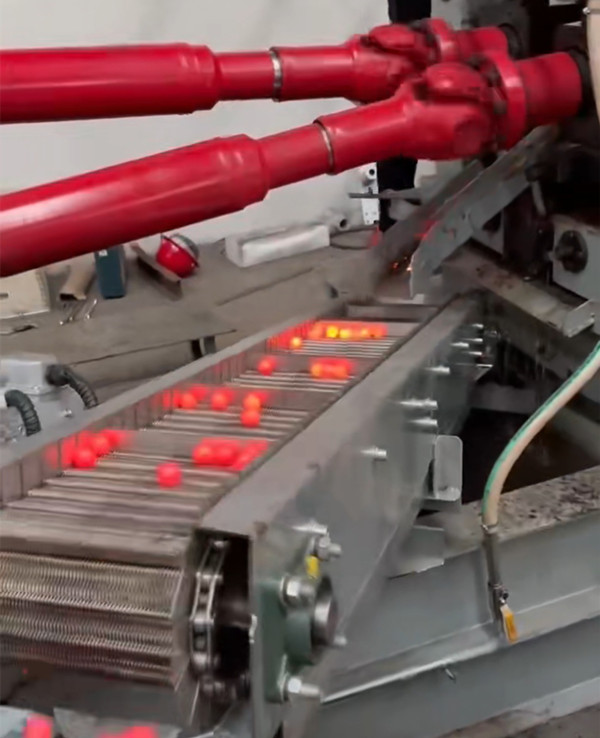

lWorkpiece Handling System: Includes conveyors, manipulators, or loading/unloading mechanisms that transport materials through the induction coil. For induction forging furnaces and industrial heat treatment furnaces, this system is engineered for high-temperature resistance and precise positioning to maintain process consistency.

lControl & Cooling Systems: A digital control panel regulates temperature, heating duration, and power output, enabling real-time adjustments and process automation. The cooling system (often water-based) prevents overheating of the induction coil and power supply, ensuring long-term reliability in continuous industrial operations.

Key Characteristics of Induction Heating Furnace

lExceptional Energy Efficiency: Unlike traditional furnaces that waste heat through radiation and conduction, industrial induction heating furnace directly heat the workpiece, achieving energy utilization rates of 60-90%. This not only reduces operational costs but also aligns with global sustainability goals.

lRapid and Uniform Heating: The electromagnetic induction process delivers heat evenly across the workpiece, eliminating hot spots and ensuring consistent material properties. For induction forging furnace, this means a faster heating cycle and improved forging quality.

lPrecise Temperature Control: Advanced digital systems allow for accurate temperature regulation within ±5℃, making induction heat treatment furnaces ideal for processes requiring strict thermal parameters—such as hardening, tempering, or annealing.

lEnvironmentally Friendly Operation: With no fossil fuel combustion, industrial heat treatment furnaces and induction forging furnace produce minimal emissions (no smoke, dust, or harmful gases) and low noise levels. This creates a safer, cleaner workplace while complying with stringent environmental regulations.

lVersatility and Durability: Designed to handle a wide range of materials (steel, aluminum, copper, etc.) and workpiece sizes, induction forging furnaces and industrial heat treatment furnace adapt to diverse industrial scenarios—from small-scale component heat treatment to large-scale forging operations.

Application Fields of Induction Forging Furnaces and Heat Treatment furnaces

lMetal Forging Industry: Induction forging furnaces are the core equipment for pre-forging heating of many key automotive components. The core transmission components of a car, such as half shafts, connecting rods, gears and bearings, all need to be rapidly and uniformly heated in an induction forging furnace before precision forging processing to ensure the stability of the mechanical properties of the components after forging and reduce the risk of cracking during the forging process.

lIndustrial Heat Treatment: As specialized industrial heat treatment furnaces, induction systems are widely used for surface hardening (e.g., gears, shafts), annealing (to soften materials), tempering (to enhance toughness), and quenching (to improve hardness). Industries such as automotive, machinery, and tool manufacturing rely on these furnaces to achieve precise material performance.

l Metal Forming and Processing: Beyond forging, industrial induction heating furnaces support processes like hot rolling, extrusion, and bending. They preheat metals to improve ductility, reducing forming forces and minimizing material waste.

With our advanced technology, high - quality products, and excellent customer service, we are confident that our industrial induction heating furnace and industrial heat treatment furnace can meet your needs and help you achieve success in the metal processing industry.

Contact us now to customize your medium frequency induction heating furnace!