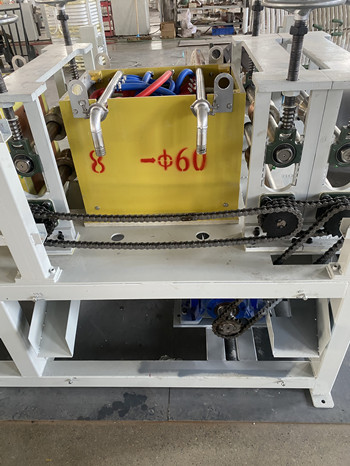

In these fields such as the metal forming and forging industry, heat treatment and surface engineering industry, automotive and transportation industry, pipe and pipe manufacturing industry, etc, the demand for efficient, precise and reliable heating solutions is constantly increasing. Our company specializes in the research, development, production and sales of medium-frequency induction heating equipment. Our industrial induction heating furnaces offer unparalleled performance and quality for metal processing and surface heat treatment.

Why must forging plants be equipped with medium-frequency induction heating furnaces?

Metal billets have high hardness and poor plasticity at room temperature. Direct forging will increase the risk of cracking, uneven deformation and internal defects. Therefore, before forging, the billet must be "heated through", and the medium-frequency induction heating furnace is currently the most mainstream and most suitable heating equipment for forging requirements in the industrial field. The core reasons are as follows:

(1) Pre-forging heating can meet the core process requirements of forging: The billet is "uniformly heated and the temperature meets the standard"

The medium-frequency induction heating furnace generates eddy currents inside the billet through the principle of electromagnetic induction, achieving "simultaneous heating inside and out". The heating depth can reach over 90% of the billet's diameter/thickness, precisely meeting the requirements of "uniform heating and rapid temperature rise". Compared with traditional heating methods (such as coal-fired furnaces and resistance furnaces), The heat penetration efficiency is increased by 30-50%, and the temperature is controllable (with an error of ±5℃), ensuring the plasticity stability of the billet during forging.

(2) Pre-forging heating can enhance the quality of forgings and optimize the internal structure of the billet

The rapid induction heating furnace has a fast heating speed (usually 1-5 minutes per section), which can reduce the oxidation and burning loss of metal billets at high temperatures (the burning loss rate is ≤1%), and prevent the formation of oxide scale on the surface of the billet, which affects the accuracy of the forging.

(3) Induction heating furnace for forging is compatible with industrial production: High efficiency, energy conservation, and automation compatibility

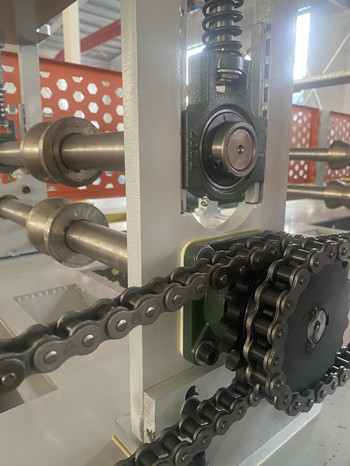

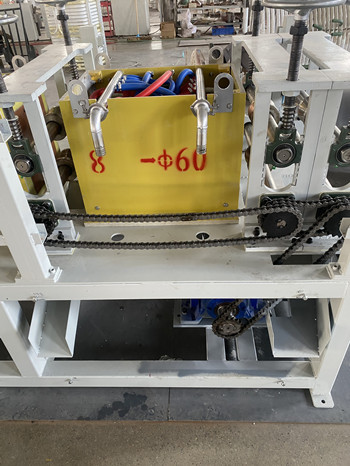

lHigh efficiency and continuity: The Induction heating furnace for forging can be equipped with an "automatic feeding and discharging system" to achieve continuous heating of billets, precisely matching the rhythm of subsequent forging machines, avoiding waiting for forging equipment.

lEnergy conservation and environmental protection: Compared with coal-fired and oil-fired furnaces, rapid induction heating furnaces reduce energy consumption by more than 30%, emit no smoke or harmful gases, and comply with global environmental protection policies.

lConvenient operation: The heating parameters (temperature, time, power) of industrial induction heating furnace can be preset through the PLC control system, eliminating the need for manual supervision and reducing the operation difficulty. At the same time, it minimizes the problem of substandard heating caused by human error.

(4) The induction heating furnace for forging adapts to different forging scenarios: Flexibly meet diverse demands

The specifications and materials of billets in forging plants vary greatly. Medium-frequency induction heating furnaces can be adapted to different requirements by adjusting the "output frequency (150-10KHZ) and power".

2. Typical process flow of forging plants: The irreplaceable position of medium-frequency induction heating furnaces

Take "forging of automotive gear blanks" as an example. The complete process is as follows: raw materials → cutting → heating → forging → cooling → heat treatment. It can be seen that the industrial induction heating furnace is the key link connecting "raw materials" and "forging" - without a industrial induction heating furnace, the blank cannot meet the requirements of plastic deformation, and subsequent forging cannot be carried out. If the heating effect is poor (such as uneven temperature and severe burning damage), it will directly lead to cracking of the forging, failure to meet the precision standards, and increase production costs.

3. Conclusion: The induction heating furnace for forging is the "production prerequisite" of the forging plant

The core value of industrial induction heating furnace lies in "providing qualified high-temperature billets for forging". It does not directly participate in forging deformation, but determines the feasibility, efficiency and quality of forgings in forging. For forging plants, the essence of choosing induction heating furnace for forging is:

Solve the process pain point that "billets at room temperature cannot be forged";

Enhance production efficiency and reduce costs (energy conservation + low burn-off);

Meet the demands of industrialization such as mass production, automation and environmental protection;

Adapt to billets of different materials and specifications to enhance production flexibility.

Especially in the international market, overseas forging plants (such as those in Europe, America, and Southeast Asia) have higher requirements for environmental protection, energy efficiency, and automation. Medium-frequency induction heating furnaces, with their advantages of "high efficiency, energy conservation, and controllability", have become their preferred heating equipment. This is also one of the core competitive advantages of medium-frequency induction equipment exports.